- home

- about hengyuan

-

business arer

- production of high performance lightweight aggregate from so

- preparation of dry desulfurizer from calcium carbide mud

- solution of water ecological treatment

- preparation of autoclaved brick from solid waste

- preparation of light and high strength thermal insulation ma

- tailings concentration and dry discharge

- tailings pumping and filling

- preparation of special cementitious material for filling wit

- product

- cases

- application of ceramsite

- news

- contact us

-

tel:

8618853622696

1、 overview:

calcium carbide mud is the industrial waste of pvc production by calcium carbide process. the annual emission of calcium carbide mud in china is about 20 million tons. although nearly 40% of calcium carbide mud has been comprehensively treated, the rest is still mainly stacked or landfilled. the bearing pressure of land and environment is very large. because the main components of calcium carbide mud are alkaline substances such as ca (oh) 2 and mg (oh) 2, the treated calcium carbide mud can be used as desulfurizer for flue gas desulfurization the ca (oh) 2 dry powder can also be used in sewage treatment plant to neutralize the free acid in the waste water, and also widely used in metallurgy, chemical industry, papermaking, sugar making, building coating, thermal insulation mortar and other industries.

the preparation of ca (oh) 2 dry powder such as desulfurizer from calcium carbide mud can save lime resources, reduce material cost, and achieve the purpose of waste to waste, which is of great significance to the circular economy and environmental protection advocated by the state.

calcium carbide slurry has been widely used in wet desulfurization because of its mature technology and remarkable effect. however, many experts and scholars at home and abroad have begun to study and do a lot of work in the production of calcium hydroxide as a dry desulfurizer. because there is no professional equipment, they can only use the process of drying calcium carbide slurry and then grinding it with a mill. in the production process, calcium hydroxide contacts co2 in the air and carbonizes, and some of it generates caco3, which seriously affects the quality of products; and in addition, the energy consumption of ball milling and drying is huge, resulting in high production cost, poor product quality and other problems. at the same time, the process investment is large and the process is complex. there are also domestic manufacturers that directly enter calcium carbide mud and lime powder into the digester because they do not have core equipment. due to the low speed, calcium carbide mud can not be fully decomposed, agglomerated particles can not be effectively dispersed, not to mention fully digested, the yield is reduced, and the quality of products is reduced.

according to the existing domestic dry desulfurization technology, combined with our company's technical advantages in the field of powder metering and mixing, digestion and other fields, and in close cooperation with domestic and foreign universities and scientific research institutes, through a large number of experimental support, our company has successfully developed the preparation of dry desulfurization agent ca (oh) 2 technology by using wet calcium carbide mud (about 8% - 40% water content) and quicklime.

in view of the existing production line for the preparation of calcium hydroxide by the digestion of quicklime, our company can carry out technical transformation according to the actual situation of the site, so that a large amount of calcium carbide mud can be added to the transformed production line, thus greatly reducing the production cost.

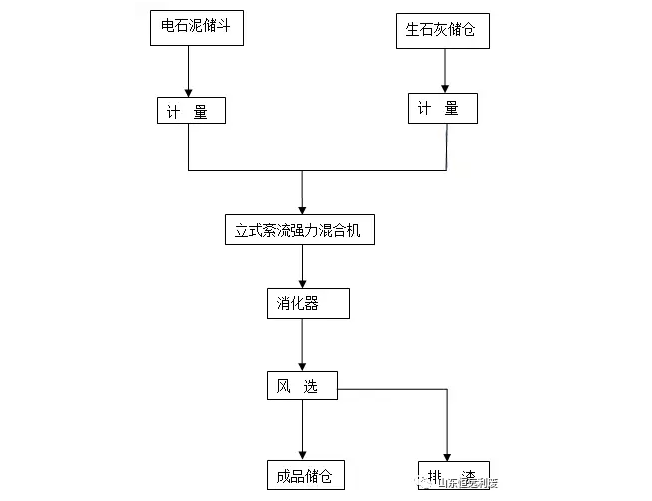

2、 introduction to the preparation process of calcium carbide mud from calcium carbide and quicklime:

1. principle: due to the fact that the water content of the calcium carbide mud is difficult to remove, it exists in particles or blocks. how to depolymerize the calcium carbide mud into a dry powder of 200 mesh to 400 mesh requires a professional equipment - vertical turbulent strong mixer. add appropriate amount of cao fragments or fine powder to the mixer. during the strong mixing process of cao and hydroelectricity containing stone mud, cao absorbs part of the water and transforms it into ca (oh) 2. the water in calcium carbide mud is taken away by cao, and is strongly mixed and refined by the high-speed rotating blades in the mixer. meanwhile, a large amount of heat released makes part of the water transformed into steam and discharged. during the homogenization process of quicklime and calcium carbide slag, cao is fully digested, agglomerated particles containing hydroelectricity stone mud are effectively dispersed, and the steam generated by exothermic heat effectively activates the production organism, so that the product has a large specific surface area and uniform particles. at the same time, in the short mixing reaction process, ca (oh) 2 cannot contact co2 without carbonization, thus ensuring ca (oh) 2 quality.

2. brief description of the process: calcium carbide mud is stored in the storage hopper and the storage bin respectively, and then transported to the strong mixing equipment after being metered by the measuring equipment; quick lime is temporarily stored in the storage bin after being crushed, and then transported to the strong mixing equipment after being metered; after the above two materials enter the strong mixing equipment at the same time, they are fully and completely contacted through the high-speed turbulent strong mixing start the digestion reaction, because of the existence of the principle described in the first article, the two materials get ideal homogenization effect. the homogenized material is further digested and dehumidified by the four-stage digester, and graded by the air separation equipment. it can be classified and stored according to the required particle grade. the unqualified particles are returned to the mixing equipment for digestion or discharged from the slag discharge port.

3. the whole production line adopts siemens plc system, with convenient ingredients, accurate measurement, stable and reliable control, which can realize intelligent production. the proportioner is a mature model equipped with arch breaking device of our company, which can realize the smooth discharge of calcium carbide mud.

4. the production line meets the requirements of national environmental protection. the whole line adopts negative pressure production in all links. the emission standard is less than 20mg / m3, the noise is less than 85db, and the digestibility is more than 97%

english

english address: no.9960, qushan road, chengguan street office, linqu county, shandong province

address: no.9960, qushan road, chengguan street office, linqu county, shandong province  service hotline: manager du 86 18853622696 / 0536-3717317

service hotline: manager du 86 18853622696 / 0536-3717317 e-mail:831785@sdhylf.com record number:

e-mail:831785@sdhylf.com record number:

about us

about us nwes

nwes