- home

- about hengyuan

-

business arer

- production of high performance lightweight aggregate from so

- preparation of dry desulfurizer from calcium carbide mud

- solution of water ecological treatment

- preparation of autoclaved brick from solid waste

- preparation of light and high strength thermal insulation ma

- tailings concentration and dry discharge

- tailings pumping and filling

- preparation of special cementitious material for filling wit

- product

- cases

- application of ceramsite

- news

- contact us

-

tel:

8618853622696

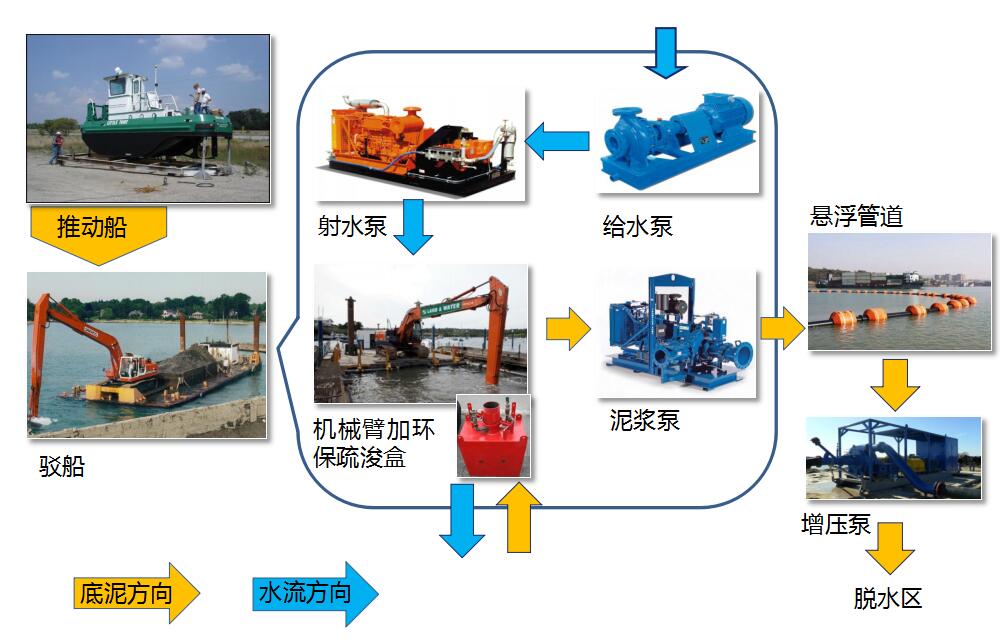

1、 zero diffusion dredging technology

1. zero diffusion, no secondary pollution

the area to be dredged under water is sealed, and the sediment is sucked into the sealing equipment through the negative pressure generated by the slurry pump, which has little disturbance to the sediment and water body, and basically no secondary pollutants are generated.

2. high dredging efficiency

the bottom sediment is disturbed by the water jet from the mechanical mechanism and the dredging box at the same time. the negative pressure directly draws the sediment out, and the efficiency is 30% higher than that of the traditional dredging method.

3. high positioning accuracy

the accuracy of water surface positioning can reach centimeter level, which can accurately locate underwater construction points.

4. controllable separation

in the construction process, the construction depth can be accurately controlled by high-precision positioning device, and its core equipment can effectively separate the target polluted sediment in the construction area.

2、 dewatering and purification technology of sediment

1. geobag method

geotube bag sludge treatment method can realize in-situ dehydration, reduce sediment volume and moisture content, and facilitate subsequent resource utilization.

2. mechanical dehydration

the mechanical dewatering method can realize the modular design of the whole dewatering process. in practice, different modules can be selected according to the mud property and working conditions.

3、 utilization technology of sediment resources

the preparation process of clay is mainly divided into batching, mixing, molding, sintering and other sections. the existing sintering ceramsite technology of our company is now developing towards modularization and mobility. in the near future, it will go to the construction site together with the dredging and treatment equipment of the sediment. it has become a complete set of assembly line for dredging, dewatering and resource utilization of sediment.

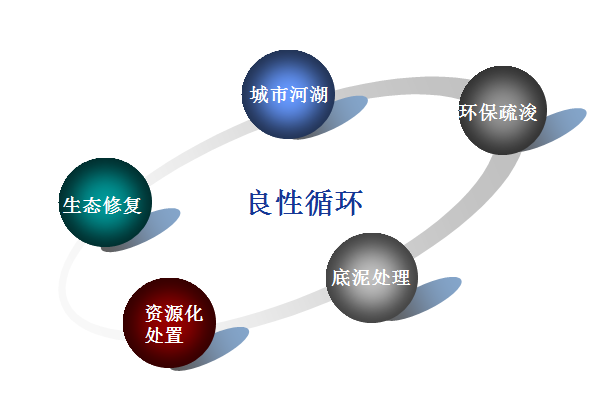

4、 ecological restoration

the ceramsite produced by the bottom mud has the characteristics of porous, light weight, heat preservation and sound insulation, and has a wide range of uses:

purpose i. ecological floating bed and constructed wetland

the ecological floating bed with ceramsite base material is to plant plants on the bed floating on the water surface, lay ultra light ceramsite on the bed, use the root system of plants and the space inside the ceramsite to absorb the pollutants in the water body, so as to purify the water quality and beautify the environment.

purpose ii. sponge city construction

ultra light ceramsite, with many pores and strong water absorption, is a very ideal sponge material for the construction of sponge city. it can absorb and lock a large amount of rainwater in the rainstorm season, and eliminate urban waterlogging; it can reduce the urban heat island effect by evaporating water in the dry or hot season. in addition, a variety of ceramsite coating can make the city more beautiful; porous structure can absorb dust, which is conducive to air purification.

in addition, because of its superior performance, ceramsite is also widely used in passive house construction, prefabricated housing construction, super high-rise building construction, etc. with the active guidance of national policies and the efforts of people from all walks of life, ceramsite will have a broader market space in the future.

5、 construction cases

english

english

address: no.9960, qushan road, chengguan street office, linqu county, shandong province

address: no.9960, qushan road, chengguan street office, linqu county, shandong province  service hotline: manager du 86 18853622696 / 0536-3717317

service hotline: manager du 86 18853622696 / 0536-3717317 e-mail:831785@sdhylf.com record number:

e-mail:831785@sdhylf.com record number:

about us

about us nwes

nwes